How 3D Laser Scanning Can Save You Time and Money

In today’s fast-paced construction, industrial, and engineering environment, the demand for accurate, efficient, and safe surveying methods has never been higher. Deadlines are tight, safety is non-negotiable, and rework is expensive. That’s where 3D laser scanning steps in—not as a trend, but as a proven tool for smarter planning and execution.

Whether you’re renovating an industrial facility, documenting as-built conditions, or designing a complex structure, 3D laser scanning delivers the high-definition clarity you need to get it right the first time.

What is 3D Laser Scanning?

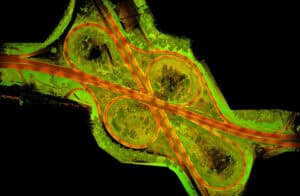

3D laser scanning is the process of capturing physical space in extreme detail using advanced laser technology. In simple terms, it works by firing laser pulses at surfaces and measuring how long they take to return. These millions of points create a “point cloud”—a detailed digital replica of your environment. Whether projects require AutoCAD, Revit, Sketchup, Navisworks or Rhino deliverables, Challenger Geomatics can help.

We’ve been using 3D laser scanning since 2007 to help to solve real problems for our clients, from architects and engineers to project managers and industrial site owners. Learn more about our 3D Laser Scanning Services here.

When Should You Use 3D Laser Scanning?

3D laser scanning is not a one-size-fits-all tool, but when used correctly it can be the most effective way to capture real-world conditions. Here are key scenarios where it shines:

1. Need to Save Time and Money

Traditional surveying methods can require multiple site visits and days of manual measurement. With 3D laser scanning, we can capture hundreds of millions of data points in just a few hours, creating a precise digital representation of the entire site.

For example, on a recent industrial project, our team used 3D laser scanning to complete a site survey that included piping and structure details, ground topography, and other details in a single day. The result? We helped the client cut weeks off their project timeline, reducing downtime and accelerating design and construction phases.

2. Safety is a Concern

Some sites are simply too dangerous or difficult to access. Whether it’s unstable ground, active machinery, or hard-to-reach elevations, safety must come first. 3D laser scanning allows us to survey from a distance, no climbing, crawling, or close-range exposure required.

3. High Accuracy is Required

One of the biggest advantages of 3D laser scanning is the level of detail and precision it provides. The high-resolution point clouds can be used to create detailed models and drawings that give engineers, designers, and contractors an exact representation of pipes, mechanical rooms, floor flatness, heritage structures, or industrial sites.

With this information, you can:

- Avoid costly rework due to inaccurate measurements

- Reduce change orders during construction

- Improve communication across teams

- Plan with confidence from day one

4. Smart Solutions for Complex Projects

Whether you’re working on an industrial facility, heritage building, or infrastructure upgrade, 3D scanning adapts to the complexity of your project. It’s ideal for:

- Retrofit and renovation planning

- Volume calculations

- Clash detection and BIM (building information modeling)

- As-built documentation

How It Helps Our Clients

At Challenger, our 3D Laser Scanning and Modelling services are built to solve real problems for our clients, from architects and engineers to project managers and industrial site owners. They are designed to meet the needs of each project, from industrial facilities and infrastructure upgrades to heritage restorations. We combine advanced technology with decades of field experience to deliver clarity, accuracy, and confidence from start to finish.

Let’s Talk About Your Project

If you’re planning a renovation, designing a new build, or facing safety concerns on a site—you don’t have to guess. Let’s talk about how 3D laser scanning can give you the clarity you need to move forward with confidence.

Contact us today to discuss your next project.